ETERLONG: Your All-In-One Solution for Blown Film Machines

ETERLONG – A merger with the leading Blown Film Die manufacturer former brand HSIN LONG. Continuation of HL spirit and experiences, in addition, ETERLONG have advanced production facilities and acquire IoT (Internet of Things) intelligent equipment to expand production capacity. We are dedicated to create All-in-One to deliver great service to make customers simple choices, they can purchase not only individual components but also complete Blown Film Machines, all from ETERLONG.

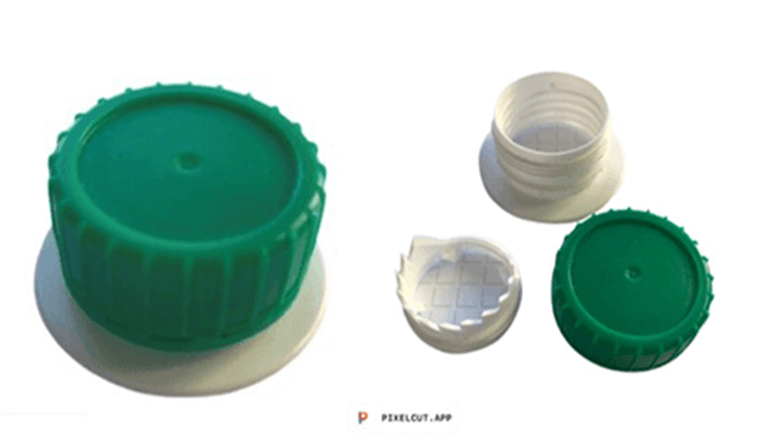

翔音:模內貼標籤

模內貼標籤是近十年來較為先進的產品貼標方式,它適用於須大量自動化生產的產品。在射出機或吹瓶機加裝供標系統即可使標籤與產品融合一併成型,無須為了貼標而進行二次加工,不僅縮短製程也能增加產能。

TUNG YU Looks Forward to Seeing You at K 2022 Düsseldorf Germany

K SHOW 2022 will be held in Düsseldorf, Germany from October 19 to 26. Tung Yu will exhibit the latest energy saving and thermal technologies and look forward to meeting old and new friends from all over the world.

TUNG YU Hydraulics will Meet You at TaipeiPLAS2022

In the post-epidemic era, companies are highly anticipating the recovery of international business, after four years of absence, TUNG YU will meet you again at the TaipeiPLAS2022 from September 27 to October 1 this year at the TaiNEX 1 Hall1. In response to the current energy transformation, carbon reduction, and zero issues, combined with green energy and industry 4.0, TUNG YU will exhibit the latest development of a full range of solutions.

Magnetic Clamping System FQA

In the current environment, it is a good time to introduce magnetic clamping system, only need one operator. This reduces labor costs and labor consumption, and the mold change speed is faster than hydraulic clamping. The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% and more of the magnetic force than traditional magnetic plate design. And SANDSUN magnetic clamping have 8 special safety function designs.

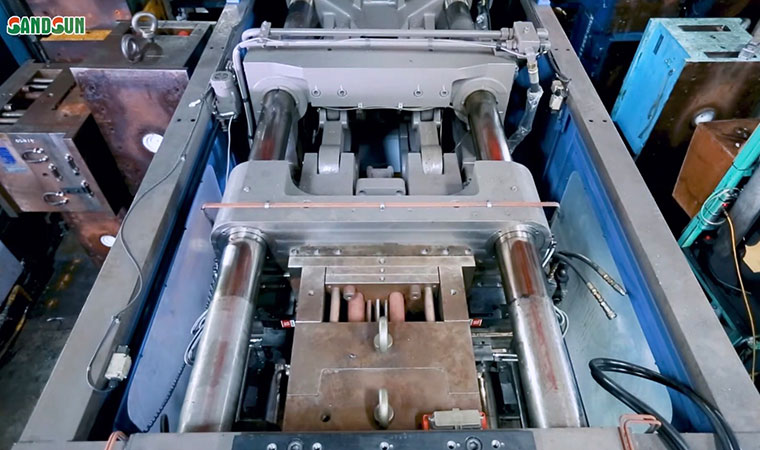

5 Tips for Efficient Injection Molding Mold Change Procedure

Regardless of the metal stamping production line or the injection molding production line, mold changing s often one of the most time-consuming procedure, and a lot of intangible waste is also generated during mold changing. In addition, in traditional mold changing process, which must rely on the master’s experience to set molds and adjust molds. However, this technical work has been gradually lost. The younger generation of employees are less willing to engage in mold changing work because this job is relatively dangerous and tired.

TUNGYU- C Type Injection Molding Machine with Rotary Table

With C type configuration to have easy operation access. Rotary table design with two molds shifting to increase production efficiency. Feeding rupture detect to prevent process from rubber shortage. With external heating platen to maintain mold temperature.

Fu Chun Shin (FCS) embraces huge potential orders in Chinaplas 2021

After a lapse of two years, the largest CHINAPLAS International Rubber and Plastic Exhibition in Asia first came to Shenzhen. During the four-day exhibition from April 13 to 16, 2021, the number of visitors reached 152,134, and it is worth noting that the official live broadcast platform has 363,000 views!

Mold-Masters E-Multi Auxiliary Equipment Provides Molder with the Capability to Maximize Productivity

The customer estimates that the time to complete the injection and assembly process has been reduced by about 50% as a result of this new system. The shrinkage occurs to all three parts evenly after assembly leading to extremely high tolerances and excellent part quality.